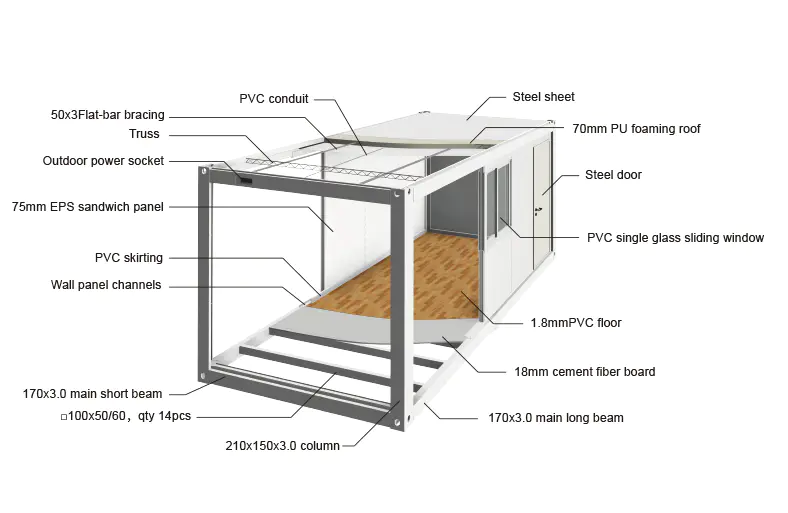

MoSteel flat pack container house is a modular structure that can be built quickly and easily. It is lightweight, airtight, and shock-resistant. The structure allows for unlimited compounding in both the longitudinal and transverse directions. It is a cost-effective and flexible way to build a home. It is also highly insulated and water-proof, which means it will not let in any moisture. Expandable container house can also be combined together to form a larger structure if needed.

For the PU foaming roof ,we have patent in China ,and we are the only factory who have this artcraft and patent in China.With PU foamed roof ,it has a good airtightness and strength.

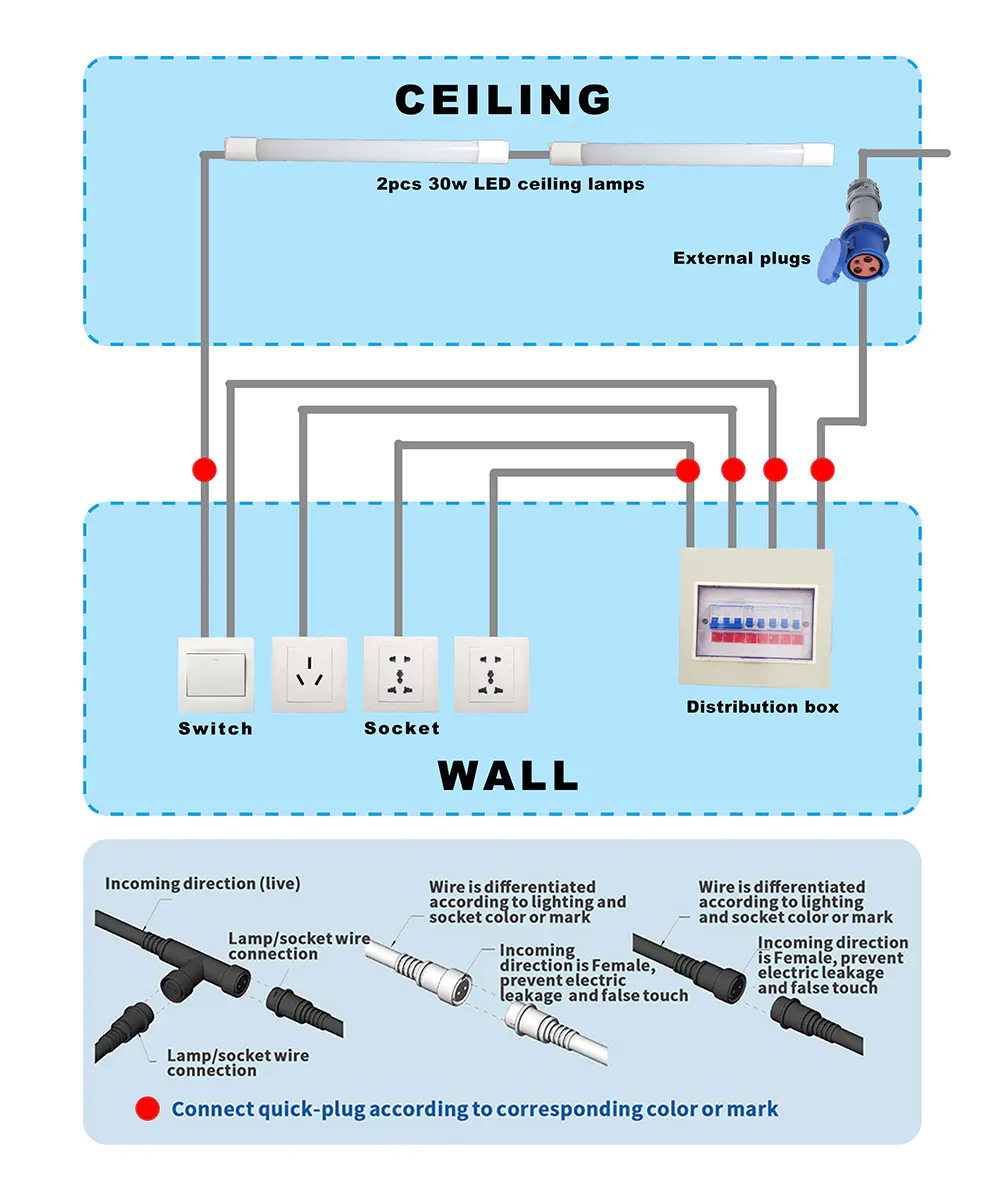

For the electrical system,we use quick plug system ,which would be much easier and faster for the installation ,it can easily handled by ppl without skill to install

| LED ceiling lamp: | 2pcs x 30w LED ceiling lamps, L=1200mm |

| Switch: | 1pc xsingle control switch (national standard rocker single control) |

| Socket: | 2pcsx10A sockets,1pc x32A 3-level outdoor waterproof inlet socket. Option: adding air conditioner socket |

| Distribution box: | 1pcx 8-circuit power distribution box, built-in 1pc x2P32A total circuit breaker (with leakage protection), 1pcx 1P lighting circuit, 1pc x1P socket circuit |

All of our frames are made automatically by robots which keep the high precision and quick making speed .Our monthly delivery can reach 2000sets